|

Ningbo Ketai Industry Co.,Ltd.

|

| Price: | 3.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Name: Gravity Casting Polished Gripe.

Experienced supplier, our company was established in 1991, Backed by China Weapon Reserch Institute Ningbo Branch.

Ningbo is the centre of Casting, maximum utilization of resourcesis a way of reduce cost.

Aluminiun Alloy List

CHINA GB/T 1173 | INTERNATIONAL ATANDARD ISO 3522 | GERMANY DIN 1725.2 | ENGLAND BS 1490 | FRANCE NF A57-105 | JAPAN JIS H5202 | AMERICA ASTM B179 |

ZAlSi7Mg(ZL101) | Al-SiMg(Fe) | G-AlSi7Mg | LM25 | A-S7G | AC4C | 356 |

ZAlSi7MgA(ZL101A) | Al-SiMg | G-AlSi7Mg | LM25 | A-S7G | AC4C | 356A |

ZAlSi12(ZL102) | Al-Si12 | G-AlSi12 | LM20 | A-S13 | AC3A | 413.2 |

ZAlSi9Mg(ZL104) | Al-Si10Mg | G-AlSi9Mg | __ | A-S9G | AC4A | 359 |

ZAlSi5Cu1Mg (ZL105) | Al-SiCu1Mg | G- AlSi5Cu | LM16 | __ | AC4D | 355 |

ZAlSi5Cu1MgA(ZL105A) | Al-Si5Cu1Mg | G- AlSi5Cu | LM16 | __ | AC4D | 355.2 |

ZAlSi8Cu1Mg (ZL106) | Al-SiMg(Fe) | __ | LM24 | A-S7G | AC4B | 328.1 |

ZAlSi7Cu4(ZL107) | Al-Si6Cu4 | G- AlSi6Cu4 | LM21 | __ | AC2B | 319.2 |

ZAlSi12Cu2Mg1 (ZL108) | Al-Si12Cu | G-Al Si12(Cu) | LM13 | A-S13 | AC3A | 383.2 |

ZAlSi12Cu1Mg1Ni1(ZL109) | Al-Si12Cu | G-Al Si12(Cu) | LM13 | A-S13 | AC3A | A413 |

ZAlSi5Cu6Mg (ZL110) | Al-Si16Cu4 | G- AlSi6Cu4 | LM21 | __ | __ | 308 |

ZAlSi9Cu2Mg (ZL111) | Al-Si10Mg | G- AlSi8Cu3 | LM2 | A-S9G | AC4B | 354 |

ZAlSi7Mg1A(ZL114A) | Al-Si7Mg(Fe) | G-AlSi7Mg | LM25 | A-S7G-03 | AC4C | 357 |

Casting Process:

Gravity Casting:

What is Gravity Casting:?

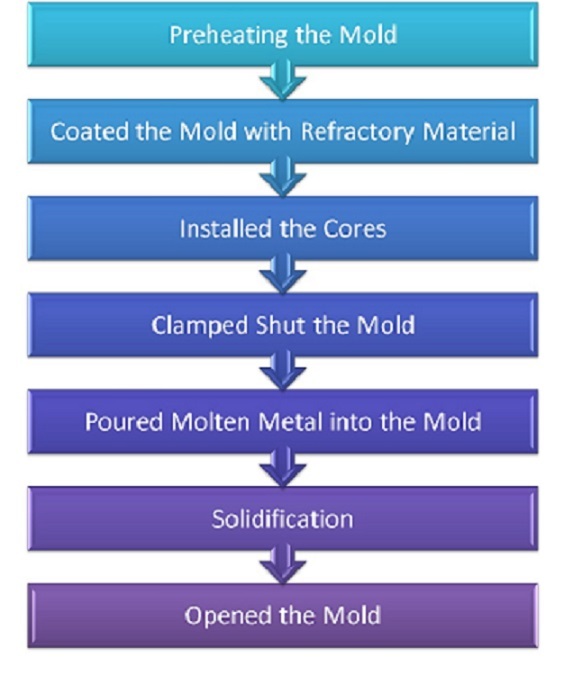

The gravity process begins by preheating the mold to 150-200 °C (300-400 °F) to ease the flow and reduce thermal damage to the casting. The mold cavity is then coated with a refractory material or a mold wash, which prevents the casting from sticking to the mold and prolongs the mold life. Any sand or metal cores are then installed and the mold is clamped shut. Molten metal is then poured into the mold. Soon after solidification the mold is opened and the casting removed to reduce chances of hot tears.

Payment Terms:

1. Payment for tooling: pay 50% in advance ,and samples will delivery within 50days, after confirmed the samples pay the balance 50%

2. Payment for goods: Pay 30% in advance ,after deliver the goods ,see B/L copy pay the balance 70%.

Reception Room:

Contact US:

Ningbo Ketai Industry Co., Ltd.

Jing No.11 Rd,Beilun Xiaogang,Ningbo China.

Tel: +86-0574-88181016

+86-0574-88181028

Fax: +86-0574-88181038

E-mail: sales@ketai-casting.com